in the present fiercely aggressive production landscape, companies confront a dual obstacle: the relentless tension to enhance performance and decrease operational costs, coupled which has a growing crucial to adopt sustainable practices. Electricity price ranges fluctuate, qualified labor could be scarce and expensive, and people and regulators alike desire greener functions. For industries relying on bottling and filling processes – from food and beverage to cosmetics and pharmaceuticals – these pressures converge specifically over the production line. common filling devices, generally rigid in design and demanding substantial manual intervention, could become bottlenecks, consuming excessive Power in the course of Procedure and changeovers, building waste, and inflating labor prerequisites. on the other hand, a different generation of liquid bottle filling machine supply is emerging, developed on the rules of adaptability and automation. These Superior programs supply a strong Alternative, directly addressing the Main difficulties by enabling multi-item adaptability and clever Procedure, paving the best way for leaner, greener, plus more financially rewarding producing. This exploration delves into how these vital features translate into tangible benefits, reworking generation flooring and environment new benchmarks for operational excellence.

Table of contents:

Taming the Changeover Beast: The Power of Multi-Specification Compatibility

Multiplying Throughput: The performance Gains of Multi-Head Filling

Empowering Your Workforce: The Simplicity of wise Human-Machine Interfaces (HMI)

making the Lean and Green Line: Automation from get started to Finish

long run-Proofing Your Investment: Adaptability and Extended products Lifecycles

Taming the Changeover Beast: The Power of Multi-Specification Compatibility

one of several most significant drains on effectiveness and assets in conventional filling strains would be the changeover system. Switching manufacturing between diverse item dimensions, designs, or formulations frequently requires sizeable downtime. This isn't just shed creation time; it is a duration of significant waste. Mechanics may need to physically swap out various structure elements or entire device sections, a method which can get several hours. through this time, Electrical power is consumed by auxiliary systems even when the most crucial line is just not functioning. demo runs right after set up generally result in material wastage – product, containers, and packaging – till the road is completely dialed in. Furthermore, the necessity to accommodate assorted merchandise portfolios generally forces suppliers to invest in various committed filling lines, Every single consuming Place, capital, and ongoing Electricity, even though idle.

fashionable filling devices engineered for versatility fundamentally adjust this equation. think about a single equipment able to managing an exceptionally wide range of container requirements – For illustration, accommodating bottle diameters from as smaller as 20mm up to 160mm, and heights spanning from 30mm to 350mm. This broad compatibility gets rid of the need for in depth mechanical reconfiguration involving lots of products runs. changes are often software program-pushed or need only slight, rapid-change tooling.

The benefits are fast and significant. Firstly, downtime is drastically reduced. Changeovers that Formerly took several hours may well now be achieved in minutes. This immediately interprets to amplified generation capability and more quickly response occasions to marketplace demands. Next, Strength usage plummets. Shorter changeover intervals necessarily mean significantly less idle Power use. additional critically, the opportunity to operate several merchandise on just one, versatile line avoids the numerous cumulative energy draw connected to running and keeping various focused, considerably less-utilized strains. Thirdly, product waste during set up and trial operates is minimized. more quickly, much more specific adjustments lessen the volume of scrapped containers and squandered merchandise. This inherent efficiency does not just spend less; it aligns properly with sustainability goals by reducing the environmental footprint affiliated with useful resource consumption and waste generation. This versatility is actually a cornerstone of lean production placed on the filling system.

Multiplying Throughput: The effectiveness Gains of Multi-Head Filling

manufacturing speed is actually a vital metric for just about any company. Increasing output for each hour directly impacts profitability and the ability to meet up with shopper orders promptly. although line velocity is crucial, the filling station itself is usually the rate-limiting stage. regular single-head fillers, though trustworthy, can only approach a person container at a time.

Innovative filling units triumph over this limitation through multi-head configurations. By incorporating a number of filling nozzles functioning in parallel, these equipment can approach numerous containers concurrently inside the similar equipment cycle. This method can produce a direct multiplication of throughput – a four-head filler can possibly quadruple the output of just one-head machine, an eight-head filler can maximize it eightfold, and so on, assuming downstream processes can hold tempo.

The influence on Power efficiency is profound. obtaining a goal creation quantity takes significantly much less operational time. If a multi-head device can fill the day by day quota in fifty percent enough time as compared to one-head device, its Over-all Electricity consumption for that creation run is greatly diminished, even though its instantaneous ability draw is a bit bigger. This translates to decreased Electricity costs for each unit developed, a essential general performance indicator for sustainable functions. In addition, this substantial-throughput functionality is particularly useful for manufacturers managing large batches of varied items. It permits swift completion of varied orders, reducing the cumulative operational hours and linked Strength use throughout the entire item combine, as compared to slower, sequential processing on fewer economical equipment.

Empowering Your Workforce: The Simplicity of clever Human-equipment Interfaces (HMI)

elaborate equipment generally demands extremely skilled operators for setup, operation, and troubleshooting. Recruiting, training, and retaining these specialized personnel is usually a substantial obstacle and expenditure. problems for the duration of guide set up can result in expensive faults, including incorrect fill volumes, merchandise spillage, or simply products harm. The reliance on specialized information could also build operational vulnerabilities if important staff are unavailable.

The integration of refined nevertheless consumer-welcoming Human-Machine Interfaces (HMIs) combined with Programmable Logic Controllers (PLCs) addresses these difficulties head-on. modern-day filling machines significantly function intuitive touchscreen interfaces that present operational parameters, diagnostic details, and Regulate capabilities in a transparent, graphical format. These methods are designed for ease of use, making it possible for operators with conventional coaching amounts to handle the equipment efficiently.

Recipe management can be a vital function enabled by PLC control. as soon as the optimum parameters for a certain product and container mixture are decided (fill volume, speed, nozzle timing, etcetera.), they can be saved like a recipe. When that product should run once more, the operator simply selects the saved recipe, plus the equipment instantly configures itself. This significantly decreases set up time, minimizes the chance of human mistake in the course of guide parameter entry, and guarantees dependable quality operate following operate. This simplicity of use not simply lowers the skill threshold required for Procedure, reducing dependence on extremely specialized labor, and also boosts All round operational performance by reducing set up problems and rushing up transitions in between goods. It democratizes device operation, creating Highly developed technology accessible and responsible to get a broader range of producing staff members.

creating the Lean and environmentally friendly Line: Automation from start out to Finish

While the filling device is central, real operational effectiveness emanates from integrating it seamlessly into a bigger automatic workflow. handbook processes like loading bottles onto the line, transferring them among stations, capping, labeling, and packing are labor-intense, at risk of inconsistency, and might introduce bottlenecks that negate the speed benefits of a complicated filler.

contemporary flexible filling machines are made with integration in mind. they will easily join with upstream and downstream automation gear, which include automated bottle unscramblers, conveyor devices, capping machines, labelers, and case packers. This produces a cohesive, automatic manufacturing line the place containers flow efficiently from begin to complete with minimum human intervention.

The benefits extend considerably over and above labor Charge reduction, Whilst That could be a primary driver, specifically in regions with superior labor expenses. Automation ensures consistency. equipment accomplish jobs frequently with high precision, reducing variability in products excellent and minimizing squander because of handling problems. Furthermore, it enhances employee security by getting rid of staff from potentially repetitive or hazardous tasks. from the sustainability point of view, a fully automated line optimizes workflow, minimizes halt-start off inefficiencies, and ensures that sources – components, Vitality, and human cash – are made use of as effectively as you possibly can. This holistic approach to automation, normally facilitated by a knowledgeable liquid bottle filling device supplier effective at coming up with integrated methods, generates A really "fewer-manned" or probably even "lights-out" Procedure, representing the top of lean and inexperienced producing principles.

long term-Proofing Your financial investment: Adaptability and prolonged gear Lifecycles

Markets evolve, shopper Tastes modify, and solution innovation is constant. companies regularly introduce new merchandise, variations, or packaging formats. With common, rigid equipment, adapting to those variations might be tricky, highly-priced, or not possible, normally leading to premature tools obsolescence. Replacing equipment prior to the finish of its possible useful lifestyle is not just a significant capital expenditure but in addition carries a substantial environmental load related to producing new machines and disposing of the aged.

The inherent adaptability of contemporary filling equipment provides a strong method of long run-proofing. for the reason that these systems are meant to handle a wide array of product types (liquids, creams, pastes) and container formats by means of parameter changes instead of important structural alterations, they can certainly accommodate new solutions as They may be designed. A machine purchased nowadays remains relevant and productive at the same time as the corporation's products portfolio expands or shifts. This concept of "1 device, a lot of works by using" maximizes the return on financial investment.

much more importantly, this adaptability significantly extends the machines's operational lifecycle. By delaying or staying away from the necessity for substitute, manufacturers reduce the need for new useful resource-intense equipment output. In addition it minimizes the squander stream linked to scrapping outdated tools. selecting devices made for extended-time period adaptability is therefore a essentially sustainable conclusion, reducing the general environmental impression linked to money goods over time. A respected paste filling machine maker specializing in this sort of adaptable types inherently contributes to a more round financial system within the manufacturing sector.

The trail to a far more financially rewarding and sustainable production long term is paved with clever investments in technology that addresses core operational problems. during the realm of product filling, the convergence of multi-merchandise more info adaptability and sophisticated automation offers a powerful Answer. By minimizing changeover waste, maximizing throughput with multi-head models, simplifying Procedure as a result of intuitive interfaces, enabling seamless line integration, and long term-proofing investments with inherent versatility, these Innovative filling units instantly fight soaring Vitality prices and labor pressures. They empower manufacturers to be leaner, additional agile, and significantly greener. the chance to lessen Power use per unit, limit material squander, and prolong gear lifecycles are now not just desirable characteristics; They're important parts of liable and competitive contemporary manufacturing. firms trying to get these Highly developed capabilities typically switch to professional companies known for sturdy and versatile methods, such as the devices designed by Jiaren, to achieve their operational and sustainability targets.

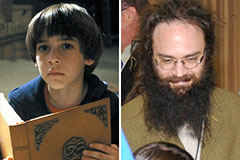

Barret Oliver Then & Now!

Barret Oliver Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!